How to check if ElmaTear is working correctly between calibrations

How can I check if ElmaTear is working correctly between calibrations?

For diagrams and images, please download the PDF document.

Use the check weights supplied with ElmaTear for a quick and easy way to verify if the instrument is performing correctly between calibrations. Checks should be performed if:

· Questionable results are seen

· The instrument appears to be performing incorrectly

· Increased validity for specific testing is needed

ElmaTear is supplied with a set of six (or seven) check weights, one for each corresponding pendulum: ¼A, ½A, A, B, C and D (and E*).

These enable the operator to confirm that the instrument is functioning correctly, but does not replace a calibration performed by a James Heal Service & Calibration Engineer.

This method provides one check point approximately mid-range of each pendulum.

Do not use check weights when verifying the pendulum (free swing test).

· Check the instrument is level

· Select a standard to measure in Newtons / single ply

· Close both jaws WITHOUT a specimen

· Fit the pendulum weight of choice

· Verify the pendulum

· Return the arm to test position

· Add the corresponding check weight

Once the check weight is in place:

· ‘Notch’ the ‘specimen’ (no specimen)

· Release the pendulum arm by pressing both buttons simultaneously

· Repeat the test 5 times to create a mean

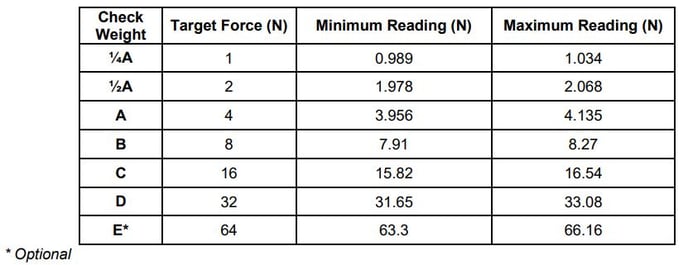

· The mean should fall between the 2 corresponding figures in the table below

Check Weights – Acceptable Parameters

If the reading is unsatisfactory, carry out checks as below, then repeat the testing of the performance of the instrument after adjustments have been made:

· Levelling

· Tightness of the locking nuts

· Tightness of knurled handwheel to prevent the weight from rotating

· Jaws are empty and closed

· Movement of the instrument – if it moves, fix to a bench

If there continues to be a problem, contact James Heal Service & Calibration.