Checking for friction on ElmaTear

Friction in pendulum bearings will have an effect on the accuracy of test results. Section A.2.4 of ISO 1974 shows a method of checking the bearing friction of a tear tester.

For a “perfect” pendulum the height to which it swings will be the same as its initial release height.

In reality when a pendulum is released any friction in the bearing will reduce the height to which the pendulum swings. If the pendulum is left swinging the height will gradually reduce.

Any friction in the pendulum bearings will have an effect on the accuracy of the test results Section A.2.4 of ISO 1974 shows a method of checking the bearing friction of a tear tester.

The method shown in ISO 1974 is count the number of pendulum swings taken until the height of the swing drops by 25mm. The count must be at least 25.

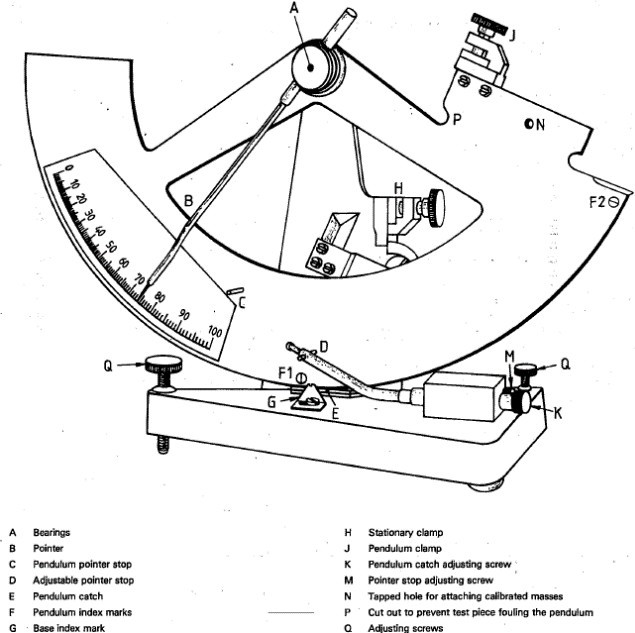

The method was written many years ago and based around the old mechanical Elmendorfs as shown in appendix A of ISO 1974.

The method is also technically flawed. 25mm on a small radius pendulum does not equate to the same friction loss as 25mm on a large radius pendulum. There is no specification for the diameter/ radius in the standard.

Since this standard was written technology has move on considerably. We believe the method shown in ISO 1974 is outdated and better methods are available. The Elmatear 1555 guards against bearing friction in 2 ways.

First, when the pendulum is verified a limit is put on how much it can drop due to friction.

This can be seen by looking at the switch angles for different pendulums. You will see the heavy pendulums such as C, D and E come near to the perfect swing angle around 150 degrees.

This is because the energy loss due to friction is small compared to the energy in the pendulum. However when using the lighter pendulums such as ¼ A and ½ A the smaller energy of the pendulum means the friction energy has a bigger effect and you may see swings angles of around 148 degrees.

If the swing angle is below 147 degrees the Elmatear 1555 will reject the verification to alert the operator of the problem.

Secondly, the swing angle measured during verification is used in any further calculations for your test results.

This compensation eliminates both the effect of friction and also the instrument not being level up to a certain extent.

In addition to our above methods of guarding against friction, our calibration method also checks each pendulum at 0%, 25% 50% and 75% points of the range.

This extensive check gives full confidence that the results given by the instrument are correct.